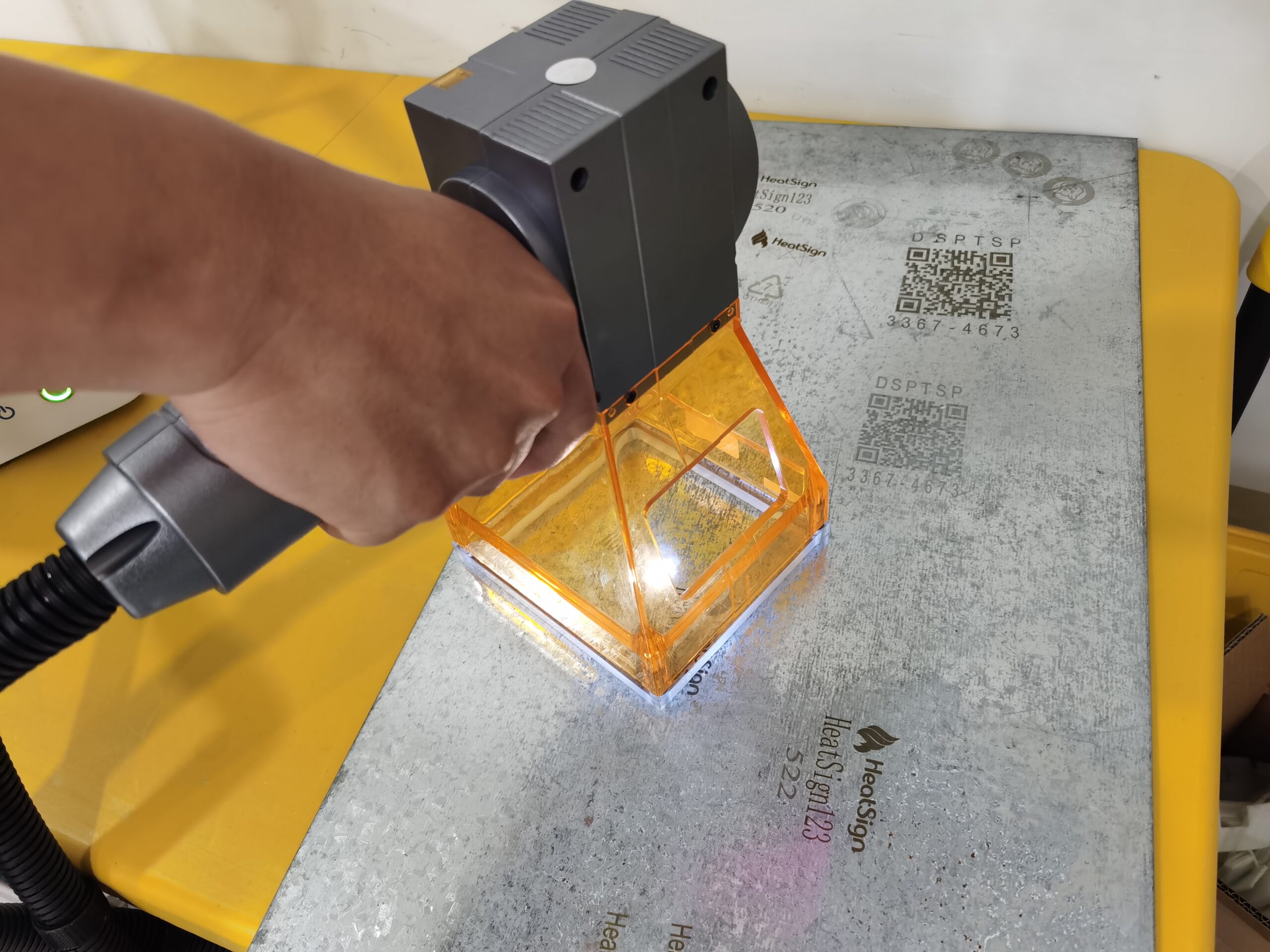

High Quality Laser Plastic Welding

Exploring the Positive aspects of Laser Plastic-type Welding

Laser plastic welding can be an advanced technology that gives numerous benefits for joining plastic components inside various industries. This specific innovative process utilizes laser energy to generate strong and specific bonds between plastic parts, offering positive aspects such as improved strength, precision, in addition to efficiency compared in order to traditional welding procedures. Let's delve into typically the key advantages involving laser plastic welding:

1 ) Precise plus Consistent Welds:

Laser plastic welding enables precise control above the welding procedure, resulting in steady and uniform welds with minimal variant. The focused laser delivers energy specifically to the welded area, ensuring ideal fusion between plastic material parts without harming surrounding material.

2. Strong and Trustworthy Bonds:

Laser plastic welding produces high-strength bonds between plastic-type components, exceeding the particular mechanical properties regarding other joining approaches such as adhesives or even ultrasonic welding. The particular welded joints exhibit excellent tensile strength, shear strength, and even durability, making these people suited to demanding software in automotive, healthcare, and electronics companies.

3. Inkjet printing plastics and Compatibility:

Laser clear plastic welding is compatible with a comprehensive portfolio of thermosoftening plastic materials, including ABDOMINAL MUSCLES, polycarbonate, polypropylene, and even nylon, among others. This particular versatility allows manufacturers to weld different plastic parts along with varying shapes, measurements, and geometries, offering flexibility in item design and assemblage.

4. Minimal Cold weather Distortion:

Unlike classic welding techniques that will rely on warmth conduction or heat, laser plastic welding minimizes thermal daub and stress within the welded components. Typically the localized heating provided by the laser light beam leads to precise melting and solidification regarding the plastic-type, keeping the integrity of the surrounding places and minimizing post-weld processing.

5. Spending Contactless Process:

Laser plastic welding is actually a clean and contactless process that gets rid of the advantages of consumables, creams, or additional materials used. The non-contact character of laser welded prevents contamination of the welded mutual and reduces typically the risk of portion contamination, making it ideal for applications requiring strict cleanliness standards, such seeing that medical device producing.

6. Automation and Efficiency:

Laser plastic material welding can be easily incorporated into computerized production lines, providing high throughput in addition to efficiency. With sophisticated robotic systems and precision optics, suppliers can achieve swift and repeatable welded cycles, resulting in increased productivity and even reduced manufacturing expenses.

7. Environmentally Good:

Laser plastic welded is an environmentally friendly joining method of which minimizes energy intake and waste era. The precise and even localized nature associated with laser welding minimizes material waste plus energy consumption as opposed to traditional welding techniques, leading to lasting manufacturing practices.

Realization:

Laser plastic welding offers a myriad of benefits for joining clear plastic components in numerous industries, including automotive, medical, electronics, in addition to consumer goods. Together with its precise, solid, and efficient welding capabilities, laser plastic material welding is revolutionizing manufacturing processes, permitting manufacturers to attain exceptional product quality, functionality, and reliability. Because the demand regarding lightweight, durable, in addition to complex plastic devices continues to grow, laser plastic-type welding remains a new key technology driving a car innovation and progression in the field of plastic signing up for.